SMITHSONIAN

AIR & SPACE MUSEUM

ACCEPTS DONATION OF PETE KING'S GC-1A SWIFT N80518!

East

Coast Swifter Pete King has been in negotiation with the National Air

and Space Museum recently, the subject is the donation of his GC-1A

Swift for display in the new NASM annex at Dulles Airport near Washington,

D.C. Pete emailed with the following news...

"It's official now !! Am very flattered that my Swift will be

seen with such rarefied company as the Concorde and the Blackbird.

After the recent forced landing in the corn field ( without damage )

-- she seemed destined to be pampered a bit. Regards, Pete"

Click on the letter below to read the

Smithsonian's acceptance of Pete's Swift!

Read more about Pete and his Swift below...

|

Anatomy

of a GC-1A... Globe Swift N80518 |

====================

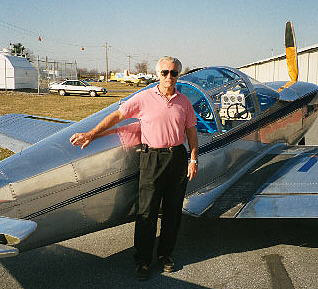

I know... I'm touching it. It will be polished soon. During the restoration of 80518, more time was spent in polishing the original skins (most of which are still on plane) than in all the mechanical restoration. I bought the Swift in 1976 from Bob Padgett, now a restoration specialist with the National Air and Space Museum. It had been wind damaged in North Caroling in 1957 while on the ground. I brought it home sitting on the back of a pickup truck. The firewall was up against the cab and other than that it was hanging out in all directions. I only had to go about 40 miles, lucky to get away with it. First flew in 1982. Now has about 1,100 hours total time. Empty weight is 1,065 pounds on a standard day, at gross weight. It can takeoff in about 1,200 ft. It will cruise at 115-120 on 6 gph or less and is as smooth and light as anything I have ever flown. I bought my first swift in 1969. I have owned a number of them since but not near enough to compete for a title with Mark Holliday and Jim Montague.

====================

Early wing tips (left) had only two corrugations. The wing lights we an after thought and their mounts were later riveted on. The fabric covered metal framed ailerons are seen only in part.

Early grills (right) were a cast magnesium alloy. When polished, there are as bright as aluminum. The early A's used a push rod driven adapter to activate a second mechanical fuel pump. The adapter mounts where the 0-200 mounts its vacuum pump. You can see the glass fuel bowl at the bottom of the pump and the adapter toward the left hand corner of the picture.

The GC-1A is the only multiseat complex, normal category airplane produced in the country with less than 100 horse power. Behind the Beech-Roby prop is a tapered crank shaft, dual fuel pump 85hp Continental C-85-12. The exhaust pipes were the only parts that I had to have reproduced. The original stainless pipes had crystallized over the years and were brittle to use.

========================

Photo taken from the right rear quarter. Note corrugated wing walks - fabric ailerons - blue Plexiglas in rear and the upper two sliding pieces of the hatch, missing wheel cover has the swift insignia.

Fabric covered-metal framed rudder and the long wire/low freq. antenna

attaching to the vertical fin and running down to each horizontal. Note

also that the rudder is not balanced.

518's panel after more than 50 years is exactly like the deluxe panel

shown in the prod manual. Also seen is the original instrument cluster

in the center of the panel including the one handed altimeter. (Adjustment

is affected by rotating the face plate instead of the hand.) Note the

manifold pressure gauge and clock to the right of the center cluster.

The gear position light lenses are jewel cut (not bowed). To the

left side is the original GE-AS-1B low freq radio. Only the "AM"

band still functions, good for music and ball games on cross-countries.

The early style yolks show up in early pictures of this plane. The

early style needle ball has no two minute marks. On the windshield center

post is the primary nav gear, an Airpath compass. The photo on the right

shows the sliding top hatch to advantage.

The original venturi was a 2" bronze unit. Note the fabric ailerons-

used on only the first 25 production birds.

"Light" landing gear - the upper trunion system is formed and welded sheet stock. The welds are almost artistic. Note the external fluid reservoir. The whole system is straight enough that is operates by the original model 25amp gear motor and pump. The gear bulk heads are screwed in top and bottom. The idler arm mounting block is a casting. Cast iron I think.

Many thanks to Pete King for providing the photos and the information used on this page.